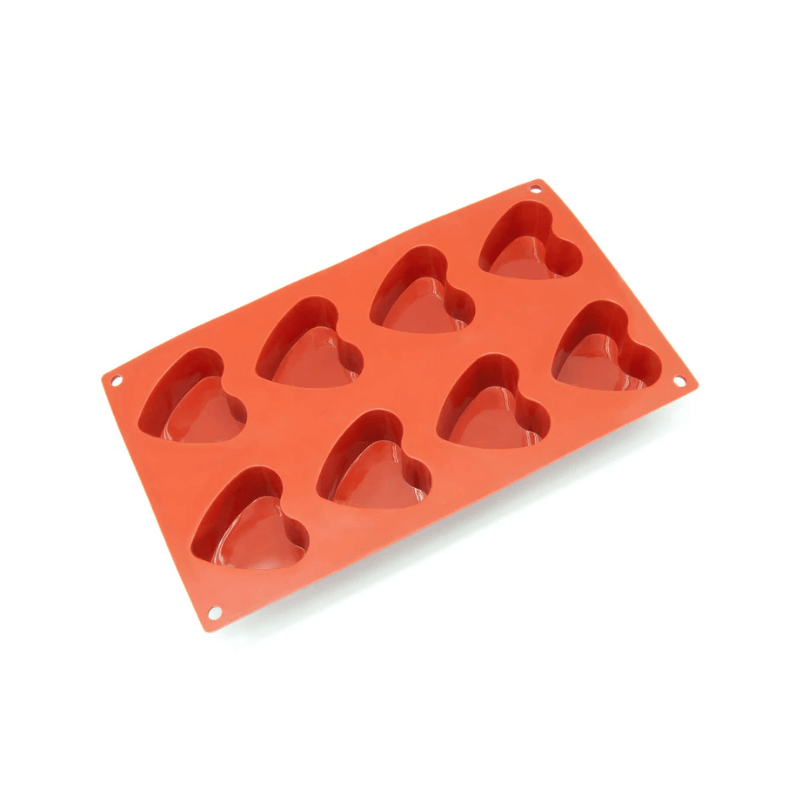

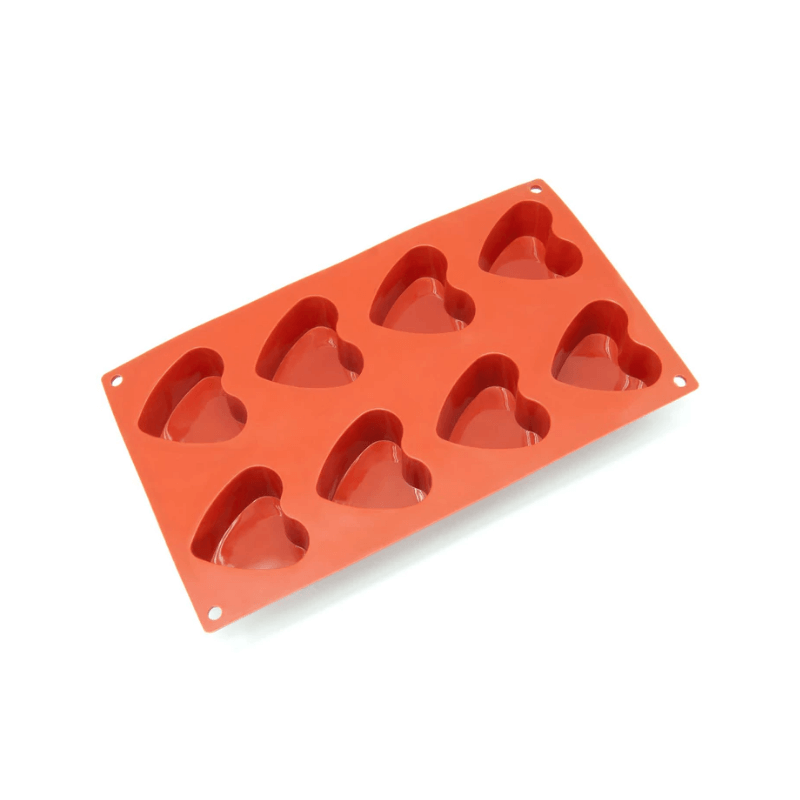

8 Cavity Silicone Mold - Heart Design

8 Cavity Silicone Mold - Heart Design

3 in stock

Couldn't load pickup availability

Cavity molds eliminate the fuss of having to cut your soaps, and make perfectly shaped bars every time. This 8 cavity heart shaped silicone mold will yield approximately 75g sized bars of soap. Mold colours may vary.

Product specifications

- Makes 8 x approx 75g heart shaped bars.

- Dimensions: Each heart cavity has the following approximate dimensions; 70mm (width; at widest point) and 70mm (height; at highest point) and 30mm (depth).

- Heat and cold resistant up to 230 degrees C

- Food grade silicone

- BPA free

- Non stick

- Microwave, open, freezer and dishwasher safe (within temperature ranges)

- Mold can be used for soaps, chocolates, jellies, cakes, puddings etc

Rose clay soap recipe

320g water, boiled and cooled or distilled

118g lye

420g olive oil infused with rose petals

70g rosehip seed oil or another oil such as pomegranate or even jojoba

225g coconut oil

80g shea butter

55g castor oil

2 tsp kaolin clay or pink clay for colour**

2 T water (you may need a little extra)

1 ½ - 2 tsp rose absolute, rose blend or geranium essential oil

A handful of fresh or dried rose petals

**You may use more clay if you wish, to make an ultra creamy bar. You can either blend it in the melted oils phase before adding the lye solution, add it teaspoon by teaspoon at trace or stir it in the batter once in the mold. Try 1-2 tablespoons to start. Your soap batter may be thicker than usual and adding clay will speed up trace.

Place the rose petals and the 320g of water in a pot and heat until a gentle simmer is achieved. Turn off the heat and let the petals steep until the water has cooled, to make an infusion. If water has evaporated, top it up to reach 320g again. Wearing safety gear, add the lye to the rose water and stir until combined. The colour of the water may turn a deeper hue but that is normal. Set the lye solution aside to cool down to between 38 and 43 degrees. Melt the coconut and shea butter, and add the other oils to the melted mixture. Allow to cool to between 32 and 38 degrees. You may now add in the additional clay, if using, otherwise add it in one teaspoon at a time at trace or stir in right at the end before molding. In a separate bowl, combine the essential oil, clay and 2 T of water. This will be added at trace or after cooking depending on whether the hot or cold process method is used.

Combine the lye solution and the oils. Blend with a stick/immersion blender for 30 seconds then hand mix to ensure everything is well mixed. Continue to alternate mixing by blender and by hand until trace is achieved.

For cold process: continue alternating immersion and hand blending until trace is reached, then add the clay mixture and mix gently but well until it is dispersed. Pour into molds and leave to set for a day or two, then unmold and cure for 4 to 6 weeks.

Simply love this mould.